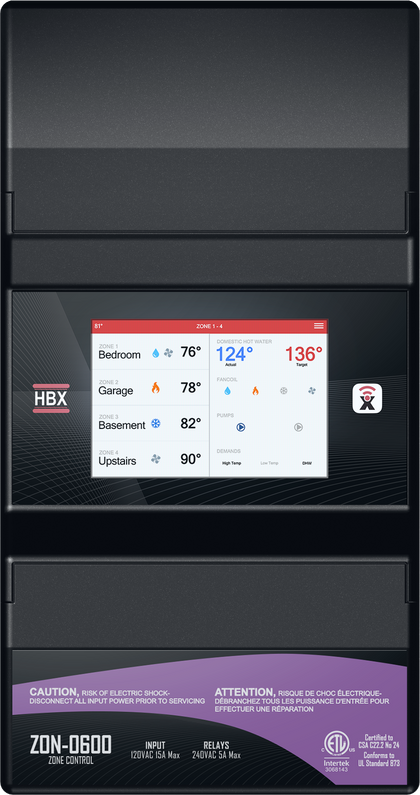

WI-FI ZONE CONTROL ZON-0600 BY HBX

This revolutionary control allows you to customize exactly your needs and wants for any application including radiant floor and forced air system control or a combination of both.

The ZON-0600 can operate zone valves or zone pumps the choice is yours. Each module allows control up to 4 individual zones with the ability of wireless expansion between modules.

Unlike your typical zone control the ZON-0600 features a full colour touch screen display that allows you to view multi-zone operation status and zone temperatures. The control features a bigger enclosure (double in size) than its predecessor (ZON-0550) for increased space for equipment wiring. The enclosure also features a brand new black glossy colour that will update and modernize any mechanical room.

Each controller is now Wi-Fi enabled eliminating the need to use the Thermolinx Wi-Fi module for online connection. Each zone can be viewed or configured from your smartphone or tablet devices, allowing you to control your comfort anytime or anywhere.

With so many features integrated into the ZON-0600 the control allows for customized options including selectable pump and demand outputs, pre and post purge run times with exercising options, and the ability to tie in an auxiliary thermistor to run a setpoint directly off the ZON-0600 (ex. DHW setpoint without using the zone output).

The new design incorporates a new pairing process that utilizes an internal Wi-Fi protocol between modules that further extends the communication distance and reduces the chance of interference with other operating systems. This process also allows for communication for demands, dampers and their priorities, amongst one another.

HBX ZON-0600 ZONE MODULE

HBX Control Systems launches the latest generation of the Wi-Fi Zoning System: the ZON-0600. This revolutionary control allows you to customize exactly your needs and wants for any application including radiant floor and forced air system control or a combination of both.

The ZON-0600 can operate zone valves or zone pumps the choice is yours. Each module allows control up to 4 additional zones with the ability of wireless expansion between modules.

Each controller is now Wi-Fi enabled eliminating the need to use the an external Wi-Fi module for online connection. Each zone can be viewed or configured from your smartphone or tablet devices, allowing you to control your comfort anytime or anywhere.

There are so many features integrated into the ZON-0600 which allows for customized options including selectable pump and demand outputs, pre and post purge run times with exercising options, and the ability to tie in an auxiliary thermistor to run a setpoint directly off the ZON-0600. Each ZON-0600 can run one (1) fan coil each with humidity.

FEATURES

• App for Android or Apple Smartphone/tablet device for remote access with alarm email notification

• Control up to four (4) independent zones per control plus one Fancoil (W-Y-G) output

• Humidity Control (X Output)

• Wirelessly expandable to a maximum of twenty (20) zones within distance

• Provides pump, valve or damper control

• Three (3) demands outputs (TT1, TT2, TT3)

• 4 pipe geo systems

Specifications:

4 x THM-0600 Thermostat Communication inputs

3 x Fancoil outputs 24VAC 2A

1X Humidity output 24VAC 2A

3 x Demand output relays 24VAC 2A

4 x Zone Relay 120VAC 5A or 24VAC 5A Input 120VAC 15A Max or 24VAC 5A

2 x Pump Relay 120VAC 5A

1x Auxiliary input 24VAC 2A Thermistor

ZON-0600 Installation

The ZON-0600 is designed to be wall mounted or installed in a separate electrical enclosure. The unit should be installed indoors and protected from falling water and high humidity conditions. With all the covers in place, it is designed to protect any individual from accidental electrical shock. It is not suitable for installation in hazardous locations and should not be close to any electromagnetic fields.

• Identify the four mounting holes on the ZON-0600, mark on the wall the desired location of mounting

• Pre-drill, anchor and fasten the two bottom screws for mounting

• Hang ZON-0600 and fasten the top two screws then tighten the bottom screws

• Complete wiring connections in accordance with local area electrical codes

STAND ALONE SYSTEM SETUP

Installation

Connect the THM-0600 thermostat to the control. If you are using a single thermostat, ensure it is connected to TH1 on the control. It is normal for the thermostat to take up to two (2) minutes to startup. The THM-0600 should not be installed in a high humidity location or where falling water is located.

Thermostat field signal wiring installation

The signal wiring that connects the ZON-0600 to each thermostat should not run parallel for any lengths with any other wires. If this is a retrofit installation and the thermostat signal wiring installation can not be verified it is recommended that the thermostats to be installed in the mechanical room with remote room (029-0022, not provided) and/or floor sensors (029-0045).

CONTROL STATUS

Sync Code - Sync Code of the ZON-0600 Wi-Fi Network – displays current SSID network connected to

Wi-Fi Password – displays password of current network connected to

Wi-Fi Strength – displays Signal strength of the network connected to

On-board Zone 1-4 (5-20) – Sync code of the connected thermostat to the associated zone. If no thermostat is connected to a zone, that zone will not be displayed.

Secondary Zones – Sync code of any LINKED ZON0600’s to this primary ZON-0600. This will only show up if this is the primary ZON-0600 and other ZON-0600’s have been LINKED.

Secondary Stats – Sync code of any thermostats from LINKED ZON-0600’s. This will only show up if this is the primary ZON-0600 and other ZON-0600’s have been LINKED.

DEMAND SETUP

Demand 1 – This chosen demand will close the contact TT1 in the upper wiring chamber

Demand 2 – This chosen demand will close the contact TT2 in the upper wiring chamber

Demand 3 – This chosen demand will close the contact TT3 in the upper wiring chamber

These demand ports are dry contacts which are rated for 24VAC and will close when there is a respective call Accept Secondary Demands – When two or more ZON-0600’s are LINKED there is the option to turn on Accept Secondary Demands. When

Accept Secondary Demands is turned to on, all Share Demands enabled on any of the Non-Primary ZON0600’s will go through the Primary controller.

Share Demands 1,2,3 – The Non-Primary controllers will have the option for Share Demand under each of its three demands. Turning any of these Share Demands on in combination with Accept Secondary Demands will allow for demands to be shared between the Primary and Non-Primary ZON-0600’s.

DEMAND SELECTIONS

HD (Low Temp) – Heat demand low temperature such as radiant in-floor

HD2 (High Temp) – Heat demand high temperature such as a fancoil or baseboard heaters (2nd stage fan coil)

AUX (Aux. Setpoint) – Demand from the auxiliary setpoint thermistor, which will close when there is a call from this thermistor

APP (App Button) – Demand from a virtual switch in the ThermoLinx app, this is a dry switch that can be used to run anything, such as a 24volt/dry switch for a fireplace, or a zone valve to shut off your water supply

CD (Cool) – Cool demand first stage

CD2 (Cool Stage 2) – Cool demand second stage, or fancoil

PUMP SETUP

Pump 1 - The chosen pump type will close the lower contact at 1-2 (PUMP1) Pump choice options explained below

Pump 1 Post Purge – (0 -240 seconds) the amount of time if necessary for Pump 1 to run after the call associated with it has been removed

Pump 1 Start Delay – (0 -240 seconds) the amount of time if necessary for Pump 1 be delayed to run after the call associated with it has been activated

Pump 2 - The chosen pump type will close the lower contact at 1-2 (PUMP2) Pump choice options explained below

Pump 2 Post Purge – (0 -240 seconds) the amount of time if necessary for Pump 2 to run after the call associated with it has been removed

Pump 2 Start Delay – (0 -240 seconds) the amount of time if necessary for Pump 2 be delayed to run after the call associated with it has been activated

Pump Exercise Time – (0 -240 hours) the amount of time that need to pass before the pumps will exercise the system pumps. (0 = no exercising)

PUMP OPTIONS

Heating – If there are any heating calls other than a fancoil heating call the pump contact will close

Cooling – If there are any cooling calls the pump contact will close

AUX – If the Auxiliary thermistor calls this pump contact will close APP – If the virtual app switch is activated this pump contact will close Fancoil

Heat/Cool – If there are any heating or cooling calls from the fancoil the pump contact will close

Fancoil Heat – If there is a heating call from the fancoil the pump contact will close

Fancoil Cool – If there is a cooling call from the fancoil the pump contact will close

System – If there are any heating or cooling calls the pump contact will close

ZONE SEQUENCE SETUP

When using more than one ZON-0600, to allow them to communicate wirelessly between each other, they will need to follow a sequential order. This specifically matters in relation to dampers, demands and priorities. Each Zone Sequence represents 4 possible thermostats (THM-0600) per zone controller with a maximum of 5 ZON-0600’s in total that can communicate. The first sequence is labelled Primary and represents sequence 1-4.

• Primary (1-4)

• 5-8

• 9-12

• 13-16

• 17-20

ZONE CONTROL ID/PRIMARY ZONE ID (1-255)

If the Zone Sequence was set to the Primary then the number under Zone Control ID will represent this ZON-0600’s ID. If the Zone Sequence was set to any sequence other than Primary, that ZON-0600’s Zone Control ID can be set to match the value of the Primary Zone Control ID and the ZON-0600’s will then LINK automatically. The ZON-0600’s will be LINKED when the Sequence Link symbol appears on the top left of the Main Screen for both controllers.

Recent Posts

-

RIB®, Power Metering, and BACnet®

One of the newer products for Functional Devices is the Power Meter. This revenue grade power meteri …2024 Apr 26th -

Wera Torque Wrench

For 14x18 mm interchangeable insert toolsEasy setting and saving of the desired torque value with …2024 Apr 24th -

RIB Relay & DC Power Packs

RIB POWER PACKS are designed to provide low voltage power to the ever-increasing sensor systems of t …2024 Apr 23rd