Tech Tip for Dry Pressure Sensors

Senva's new dry pressure line is sure to satisfy your need for performance and value. Top of the line is the P6 with ten versatile adjustable ranges in a Nema 4 housing. The P5 universal dry pressure transmitter converts from duct to panel mount in seconds with selectable pressure ranges and analog outputs. For those on a specific mission, the P4 offers economical range/output options in a cost effective and versatile package. Senva's dry pressure dry media pressure transmitter accurately measures multiple ranges optimized for building (zone) pressure, filter measurement, and static duct applications.

Don't be mislead by Pressure Accuracy Specs |

See Senva's P4 Precision Products |

How to Save Panel Space |

Reduce the required panel space for pressure devices Panel space is valuable - we prefer not to waste it! Senva's P4 and P5 are the slimmest pressure sensor on the market. Fit 3X as many sensors compared to the leading competitor by side-mounting or 1.5X if you prefer standard flat mounting for (optional) LCD viewing. All models come ready for either position as well as being easily configurable for duct-mounting. |

|

Recent Posts

-

WERA Advent calendar 2025, 28 pieces

The 2025 Wera Advent calendar includes a comprehensive screwdriving workshop for the most common sc …2025 Nov 19th -

Wera Bicycle tool set

Bike tool set with ratchet, bits, sockets and a bitholding screwdriver in the very compact Tool-Che …2025 Jul 24th -

DUCT CARBON DIOXIDE TRANSMITTER

The duct CO2transmitter uses a highly accurate andreliable non-dispersive infrared (NDIR) sens …2025 Apr 3rd

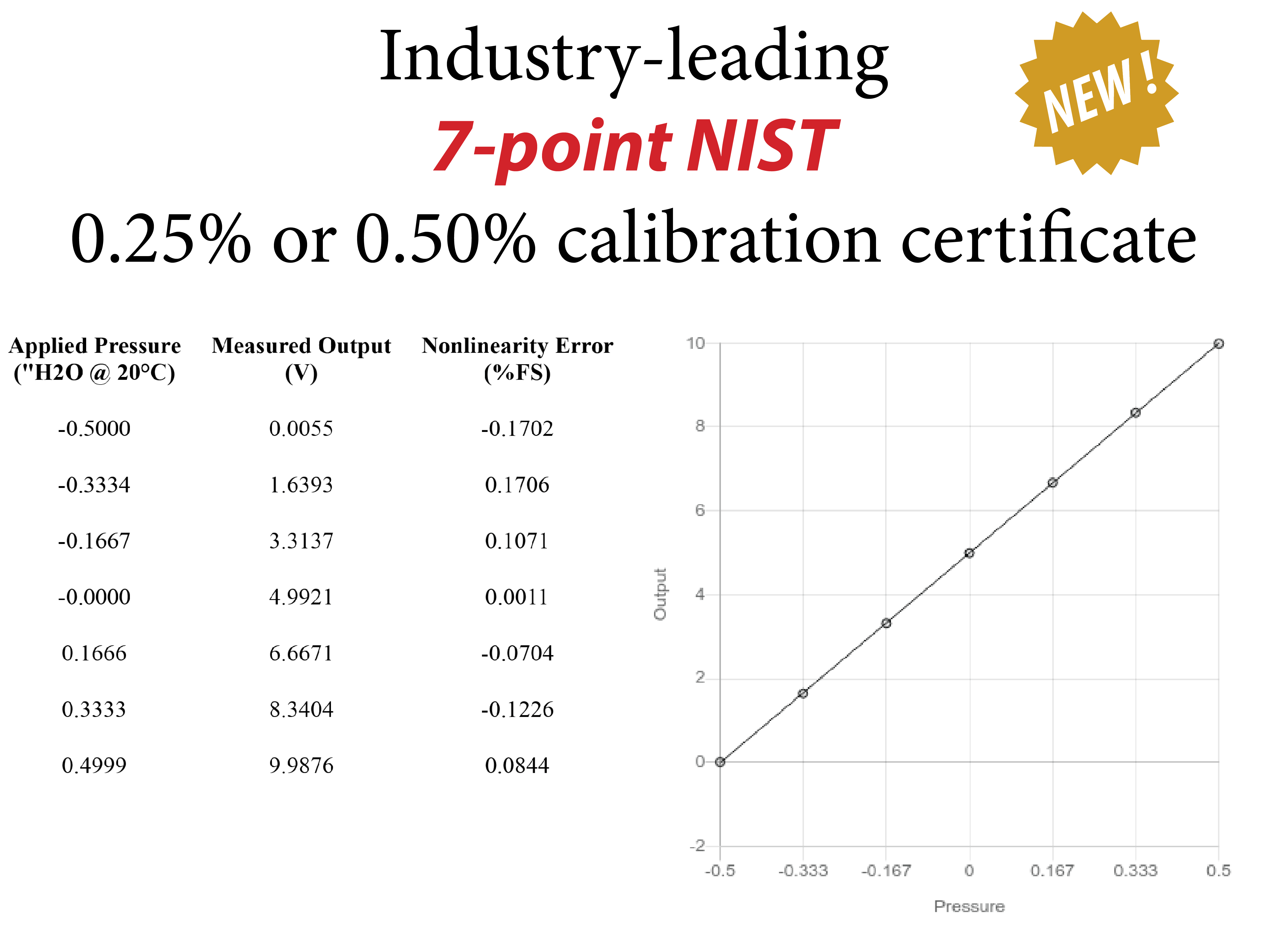

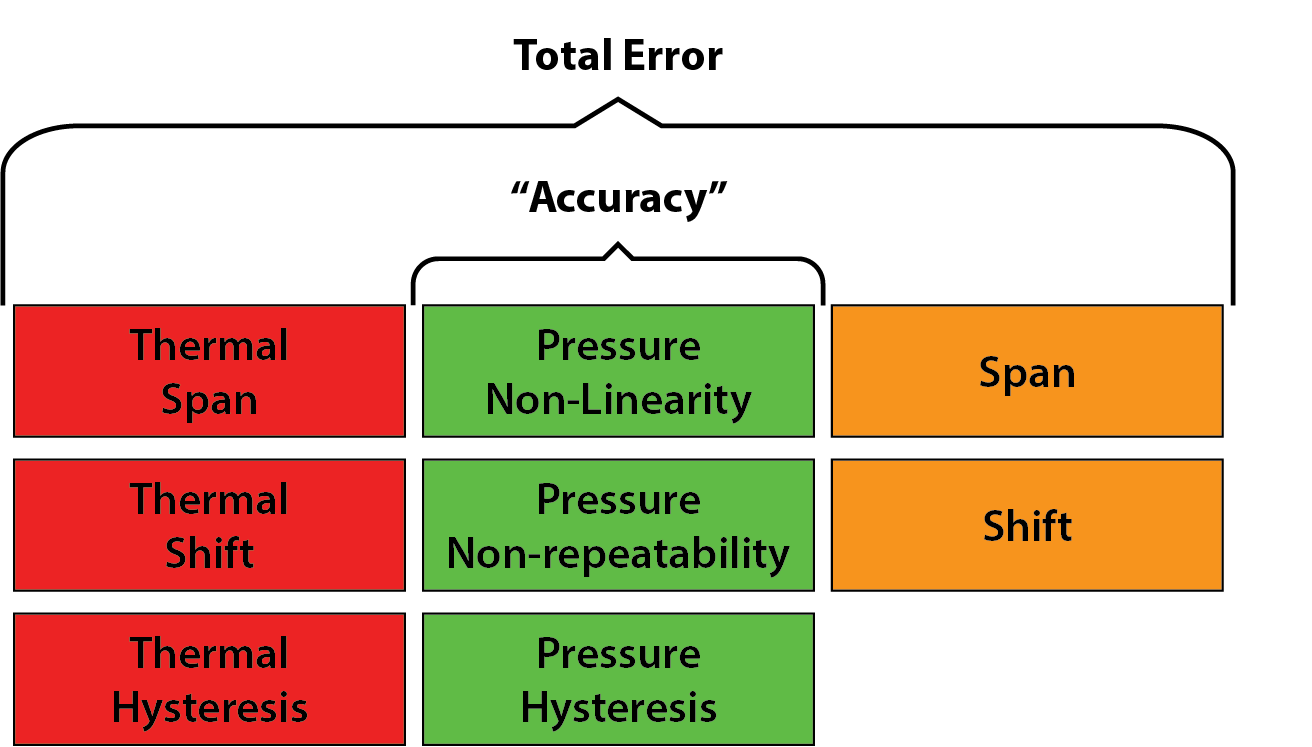

The portion we call accuracy (green) is what you typically see on a specification. You may also see best-fit-straight-line (or BFSL) which is the non-linearity element of accuracy. These three elements are fairly straight forward and available in most specs, so we won't delve too far into them.

The portion we call accuracy (green) is what you typically see on a specification. You may also see best-fit-straight-line (or BFSL) which is the non-linearity element of accuracy. These three elements are fairly straight forward and available in most specs, so we won't delve too far into them.